Winding techniques have come a long way, evolving from simple manual processes to sophisticated automated systems that power various industries. At the heart of many electrical devices lies motor winding, a critical component in ensuring efficiency and performance. As technology advances, so do the methods used to create these essential parts.

With an increasing demand for precision and quality in manufacturing, understanding different winding techniques has never been more important. From intricate coil designs to specialized applications across diverse sectors, there’s much to explore. Let’s dive into the world of winding technology and uncover how modern machines are revolutionizing this crucial aspect of engineering.

Types of Winding Machines and Their Applications

Winding machines come in various forms, each tailored for specific applications. These machines play a crucial role in the production of components that require precision and efficiency.

- One common type is the automatic coil winding machine. This device winds wire around a core to create coils used in transformers or inductors. Its speed and accuracy make it indispensable in industries such as electronics.

- Then there are toroidal winding machines, designed specifically for creating toroidal coils. Their unique shape allows for lower electromagnetic interference, which is essential in high-performance audio equipment and power supplies.

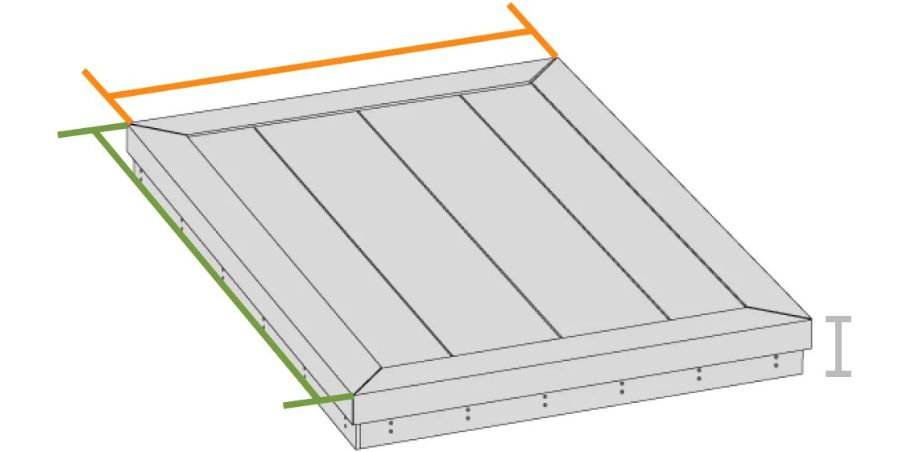

- Layer winding machines also have their place. They excel at building up layers of wire evenly, often seen in electric motor manufacturing where consistency is key to performance and durability.

- Each type serves distinct purposes while pushing the boundaries of what’s possible with motor winding technology.

Advanced Winding Techniques: Coil winding, Toroidal winding, Layer winding

Coil winding is a fundamental technique in motor manufacturing. It involves wrapping wire around a core to create electromagnetic coils. Precision in this process is vital, as it directly impacts efficiency and performance.

Toroidal winding offers distinct advantages. This method forms coils into a doughnut shape, minimizing losses due to its closed magnetic path. It’s particularly useful for transformers and inductors, enhancing their efficiency significantly.

Layer winding provides another layer of sophistication. By stacking layers of wire neatly on top of one another, manufacturers can optimize space while ensuring uniformity in the coil structure. This technique helps manage heat better and improves overall durability.

Each advanced winding technique serves specific purposes within various industries. As technology evolves, these methods continue to adapt, pushing the boundaries of what’s possible in motor design and function.

Industry-Specific Machine Applications

Different industries leverage winding technology for their unique needs. In the automotive sector, precision motor winding ensures efficiency and durability in electric vehicles. Here, the focus is on achieving optimal coil designs to enhance performance. In the aerospace industry, lightweight materials are crucial. Advanced winding techniques create components that reduce weight without sacrificing strength. This application supports innovations in aircraft design and fuel efficiency. The medical field also benefits from tailored motor windings. Devices such as MRI machines rely on precise electromagnetic coils for accurate imaging results. Renewable energy systems utilize specialized winding machines too. Wind turbines require robust coils designed to withstand harsh conditions while maximizing energy capture. Each application demands a specific approach to ensure quality and reliability, showcasing how versatile winding technology truly is across sectors.

The Evolution of Winding Technology: From Manual to Automated Processes

The journey of winding technology reflects the advancement of manufacturing capabilities. Initially, motor winding relied heavily on manual labor. Skilled workers meticulously wrapped wires around cores, ensuring precision but often resulting in inconsistencies. As industries evolved, so did the demand for efficiency and uniformity. The introduction of semi-automated machines marked a turning point. These machines assisted operators by improving speed while maintaining quality control. In recent years, full automation has revolutionized the field. Advanced robotics and computer-controlled systems now execute intricate winding patterns with unparalleled accuracy. This shift not only boosts production rates but also reduces human error significantly. Smart technologies have further enhanced this evolution. Machine learning algorithms analyze performance data to optimize processes continuously, ensuring that every coil meets stringent specifications without excessive oversight from operators. The landscape is changing rapidly as innovations emerge, transforming how we approach motor winding today and paving the way for future advancements in winding technology.

Future Possibilities and Innovations in Winding Technology

The future of winding technology is poised for remarkable transformations. Advancements in artificial intelligence are set to enhance precision and efficiency in motor winding processes. Smart machines will analyze data trends, optimizing production lines with minimal human intervention.

Next-gen materials could revolutionize coil design. Researchers are exploring superconductors that promise higher performance and reduced energy loss, leading to more efficient motors.

3D printing may also play a significant role. This technique allows for complex geometries that were previously unattainable through conventional methods. It opens doors to custom designs tailored for specific applications.

Sustainability is another critical focus area. Winding technologies will likely shift toward eco-friendly materials and practices as the industry adapts to environmental concerns.

Collaboration among innovators across sectors can lead to breakthroughs we can’t yet imagine, making the next decade an exciting time for winding technology enthusiasts.

Conclusion

Winding technology continues to evolve, reflecting the demands of various industries and the ever-growing need for efficiency. With advancements in machine applications, we see a shift from traditional manual methods to sophisticated automated processes that enhance precision and productivity. Techniques such as coil winding, toroidal winding, and layer winding have revolutionized how manufacturers approach motor winding. As we look ahead, the future promises even more innovations. The integration of smart technologies into winding machines could lead to greater customization options and improved performance metrics. This ongoing evolution ensures that businesses can adapt quickly to market needs while maintaining high standards of quality.